Commercial divers

The use of divers is frightening some project managers, because it involves techniques and know-how that are beyond their control. Research offices are often poorly informed and incompetent in this matter, but as they are confronted with it, to protect themselves they try to minimize its use. Yet the reality on construction sites is quite different and the use of professional divers is essential. CLAS has chosen to address the problem and provide answers. This philosophy has made us the only company in the world that teaches professional divers for safety techniques in the implementation of the ACCROPODE™, ACCROPODE™II, ECOPODE™, CORELOC™ and X-bloc® blocks.

The diver directs the placement of an ACCROPODE™II in Cerbères by direct communication with the crane operator.

What we heard about divers:

"It is forbidden to use divers on breakwater construction sites".

"Divers must not intervene on construction sites where ACCROPODE™ or X-bloc® blocks are used".

"It is impossible to use divers at night".

"Divers can put ACCROPODE™ but not X-block®".

"A diver cannot direct the placement of more than ten CORELOC™ per day".

"There are a lot of accidents with divers."

All this is false and the cause is certainly due to ignorance and fear, reinforced by the reprehensible behavior of companies or non-professional individuals.

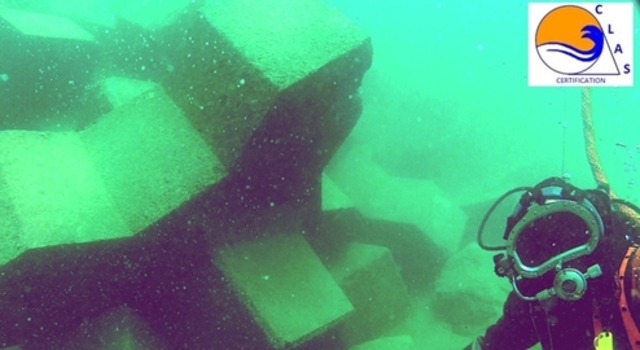

Diver come back after the placement of ACCROPODE™II in Constanta.

The reality of the difficulties that exist on these sites requires the use of professional divers to accomplish precision tasks that even advanced mechanical tools and acoustic tools cannot accomplish.

1 The tasks entrusted to divers who cannot be performed otherwise without risk of damage to the work:

- Localized adjustment of slopes and berms by palcing or removing rocks.

- Dismantling of non-conformities in the interlocking of the ACCROPODE™, ACCROPODE™II, ECOPODE™, CORELOC™ and X-bloc® blocks.

- Removal of rocks fallen on the blocks or between the blocks.

- Evidence of non-conformities generated by ECHOSCOPE® and POSIBLOC™ tools that are not visible with multibeam sonars.

- Inspections under zero risk for CLASS A armour layer.

The diver found a non conformity no identified by the ECHOSCOPE®

2 Our approach to fulfilling these tasks is as follows:

For each mission there are risks that must be clearly identified.

CLAS is specialized in the analysis of the risks specific to your project, whether you use ACCROPODE™, ACCROPODE™II, ECOPODE™, CORELOC™ or X-bloc®.

For each risk, the working procedure must be adapted to protect the staff.

CLAS develops the procedures adapted to your project, in collaboration with your safety engineers, whether you use ACCROPODE™, ACCROPODE™II, ECOPODE™, CORELOC™ or X-bloc®.

The safety procedures specific to the ACCROPODE™, ACCROPODE™II, ECOPODE™, CORELOC™ or X-bloc® blocks must be integrated in the QAQC and HSE procedures of your project and the IMCA and HSE safety rules specific to diving work. When there is no specific regulation in the country concerned by the project, CLAS adapts to local practices in order to better supervise the teams, to teach them progressively the behaviors that guarantee their safety and to accompany you from the beginning to the end of the project.

CLAS inspectors are able to use all the equipment that exists and can integrate all teams from all countries.

3 Training of diver and non-diver personnel.

Safety procedures are not ink on paper. They are the essential tool for ensuring the safety of people.

All CLAS inspectors have practical experience in pedagogy which is implemented in several stages:

Assessment of competence and the concept of danger.

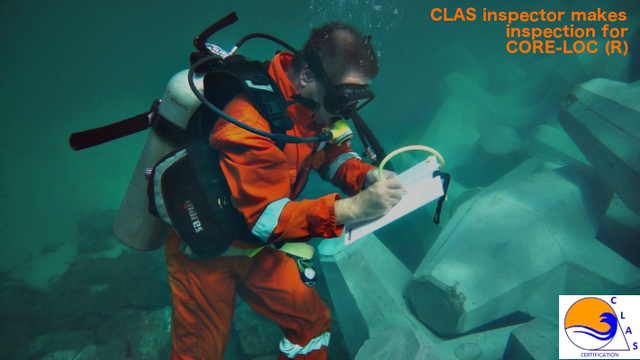

CLAS Inspector evaluates divers for CORELOC™ inspection on placement using the CHOSCOPE®

Training of divers and non-divers in safety rules in the construction of armour using the technologies ACCROPODE™ ACCROPODE™II ECOPODE™ CORELEOC™ and X-bloc®

CLAS inspectors train divers and supervisors to repair unidentified nonconformities by installing with the CHOSCOPE®

Evaluation of the personnel trained in real construction situation in coordination with the project management and the HSE department of the company.

The CLAS inspector trains underwater a diver who visually supports the installation of ACCROPODE™

The ECHOSCOPE®, POSIBLOC™ and multi-beam sonar technologies cannot identify all non-conformities or sometimes signal non-conformities which in reality do not exist. These are the limitations of these systems, which severely penalize companies.

CLAS inspectors know how to develop and teach to your divers special procedures to compensate the limitations of these tools and still allow you to build a CLASS A armour whether you use high resolution sonar, ECHOSCOPE® or POSIBLOC™.

The non-conformity diagnoses reported by CLAS inspectors in extreme conditions and without visibility were validated 100% by the same inspections in clear water a few days later.

The non-conformities reported by the ECHOSCOPE® system and the high-resolution sonars that our inspectors were challenging were found to be due to the limitations of these devices and our notices confirmed in clear water a few days later, avoiding unnecessary disassembly.

Senior Inspectors CLAS validates a procedure for identifying nonconformities in loaded water.

The inspection carried out by CLAS inspectors is more accurate and reliable than the POSIBLOC™ and ECHOSCOPE® tools which must remain tools for installation. Block imbrication cannot be properly evaluated with a high-resolution sonar. All the comparative tests between the acoustic image and reality, which were carried out by independent inspectors in collaboration with the QAQC departments of the companies, concluded in the same way:

The interlocking of the ACCROPODE™, ACCROPODE™II, ECOPODE™, CORELOC™ and X-bloc® blocks cannot be properly evaluated with acoustic systems. The armours thus approved are armours CLASS B.

Example of a safety evaluation report given to the company by CLAS inspectors during training using the ACCROPODE™II, CORELOC™, ACCROPODE™, ECOPODE™ and X-bloc® blocks. This evaluation of the staff includes the visual management of the installation, the installation with ECHOSCOPE® or POSIBLOC™ the dismantling of non-conformities not identified with ECHOSCOPE® or POSIBLOC™ and sonar high resolution, as well as the inspection to avoid dismantling useless on false nonconformities reported erroneously by these tools.

Test ECHOSCOPE® Test POSIBLOC™

|

Name |

Function |

Phot |

|

Jean Pierre Durand |

Diver |

|

|

Theoretical safety induction for ACCROPODE™II repairs, inspection and assistance for construction. 19 May 2014 |

||

|

|

Understood |

Applied |

|

General information

|

Yes |

Yes |

|

Slinging rules

|

Yes |

Yes |

|

Placing rules

|

Yes |

Yes |

|

Practical safety induction on the training slope. 21 May 2014 |

||

|

Management of the placement safely

|

Yes |

Yes |

|

Removing ACCROPODE™II

|

Yes |

Yes |

|

Communication with the excavator. 21 May 2014 |

||

|

Radio |

Yes |

Yes |

|

Hand signal |

Yes |

Yes |

1,000,000 blocks inspected, placed or repaired. CLAS inspectors have no accidents with the divers they have tested and approved.

PRAT DE BAIX EDIFICI F PB3, SOLDEU, AD100 CANILLO

+376 354 698 / +336 161 602 74

e...@clascertification.com

Clas certification - 2018 - Tous droits réservés - Mentions légales - Design : Pygmalis - Intégration : Ingeitec