POSIBLOC™

The POSIBLOC™ system was developed by ARTELIA and its partners. It is marketed by MESURIS.

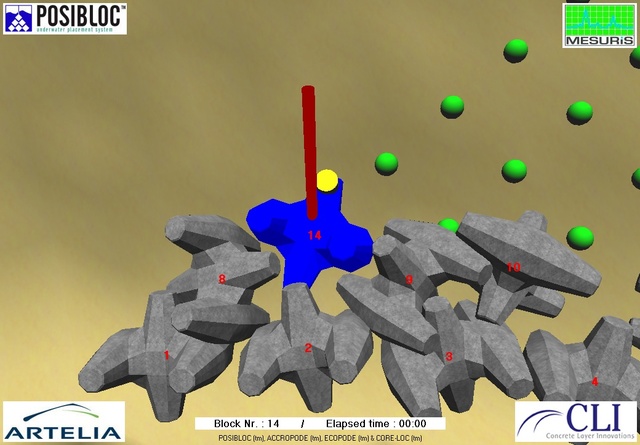

The POSIBLOC™ principle is based on measurement. It works with a virtual 3D visualization software VISIBLOC™ which allows to visualize in real time the information supplied by the measuring equipment.

The VISIBLOC PROCESSING software can be used after installation to perform various operations and manipulations from the collected datas. The information on the position of the block is transmitted to the computer by a cable connected to a sensor fixed on the concrete block by plastic plugs.

The accuracy is + or - 0.15 meters.

Our inspectors worked with the POSIBLOC™ system on the RAS LAFFAN yards in QATAR with the block ACCROPODE™, KHALIFA to ABU DHABI with the block ACCROPODE™, BARAKAH to ABU DHABI with the blocks CORELOC™ and ALFAW in IRAK with blocks CORELOC™.

The POSIBLOC™ system allows dynamic real-time monitoring of the block during installation. The other blocks are displayed on the screen in the position where they were recorded.

CLAS did a complete valuation of the POSIBLOC™ in August 2017

A CLAS inspector remained a full month at the ALFAW site in IRAK where three POSIBLOC™ were to be implemented. We have seen an improvement in the system compared to what we saw on the RAS LAFFAN, KHALIFA and BARAKAH projects where the POSIBLOC™ system was abandoned by the contractors.

Some difficulties arose:

The VISIBLOC PROCESING software also did not allow to calculate the packing densities and presented a difference of the order of 2,45% with the calculation made by AUTOCAD using the same datas.

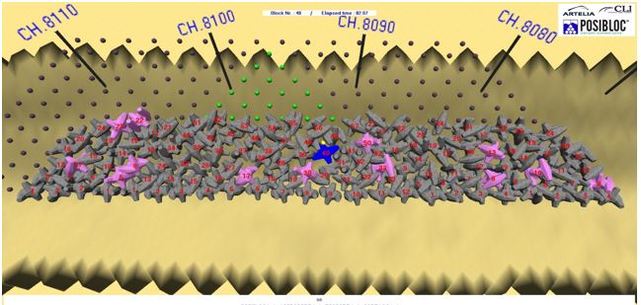

The software also did not allow to identify the blocks out of profiles. It had a lot of blocks out of profiles that were not.

The blocks colored in pink are indicated as out of profile by the software VISIBLOC PROCESSING but only one of them was really out of profile.

The interlocking of the blocks could not be appreciated properly because the software shows interlocking defects that do not exist or doesn’t show existing bad interlocking.

CORELOC™ well placed on the screen but not well placed in reality (pictures made at the same time)

The same CORELOC™ not well interlocked on the screen but well interlocked in the reality (pictures made at the same time)

The POSIBLOC™ system and its software did not identify the broken blocks. The weight sensor is intended to adjust the cable tension at the time of data recording. It is not designed to appreciate the weight in the water knowing that the limit of rupture accepted by CLI is 2% for the CORELOC™.

Some existing holes were not shown on the VISIBLOC ™ software. The software indicatessome holes that do not exist.

Defects in contacts with the underlayer not indicated on the software.

All these problems were reported to MESURIS and CLI but had not been resolved when the CLAS inspector left the project after a month of testing.

We recommend to not use the POSIBLOC™ system to approve the placement of the ACCROPODE™, ACCROPODE™II, ECOPODE™, CORELOC™ or X-bloc® blocks.

The VISIBLOC-PROCESING software makes it possible to modify the representation of the blocks, either on the orientation or on the actual position. It is not compatible with a tool to appreciate the reality of construction.

If you wish to use it as a tool to help you for the placement of the concrete blocks, we recommend that CLAS inspectors be given the task of evaluating its effectiveness in the context of your project.

The productions provided by the POSIBLOC ™ system that we saw in 2017 are an average between 3 and 4 units per hour in continuous supply. This low production is explained by several factors:

Fixing of the sensor on the concrete.

The need to install gently to avoid damaging the sensor and its cable.

The need to control the points of contact with the 3D visualization software.

The wrong information given by this software which in the majority of cases imposes to raise and to replace the same block several times.

The rather frequent tearing of the sensor, which forces the block of water to come out again to reattach the sensor.

At each attempt to pose it is necessary to again implement 3D visualization.

PRAT DE BAIX EDIFICI F PB3, SOLDEU, AD100 CANILLO

+376 354 698 / +336 161 602 74

e...@clascertification.com

Clas certification - 2018 - Tous droits réservés - Mentions légales - Design : Pygmalis - Intégration : Ingeitec