Assess a damaged armour

ASSESSING DAMAGE ON A BREAKWATER ARMOUR USING

ACCROPODE™, ACCROPODE™II, CORELOC™, ECOPODE™ ou X-bloc ®

We are not dealing here with large slides, we do not have an example applicable to breakwater armour in single-layer blocks.

Damage to an ACCROPODE ™, ACCROPODE ™ II, CORELOC ™, ECOPODE ™ or X-bloc ® breakwater is generally discreet at the start of damage and can lead to partial or total reconstruction of the armour protection if they are not detected early enough .

ACCROPODE™ broken in their place due to underwater movements

The expertise of an ACCROPODE ™, ACCROPODE ™ II, CORELOC ™, ECOPODE ™ or X-bloc ® armour can intervene at two stages:

Stage 1: as part of the normal monitoring of the structure, anomalies characterized by broken ACCROPODE ™, ACCROPODE ™ II, CORELOC ™, ECOPODE ™ or X-bloc ® are detected.

ACCROPODE™ broken and extracted after underwater movements

Stage 2: serious damage has occurred.

Collapse of an ACCROPODE ™ armour part

FIRST CASE

The monitoring of the work shows broken ACCROPODE ™, ACCROPODE ™ II, CORELOC ™, ECOPODE ™ or X-bloc ®

The first thing to do is to be interested in the design of the work:

What was the project swell used to design and what were the swells that have reached the structure since its construction?

This first study will determine if the structure has been designed to cope with a fifty-year, centennial or other swell, if it has been designed so as not to present disorders in the face of its project swell or if maintenance work has been carried out were planned from conception.

The conclusion of this study will tell the client if the disorders found are part of the normal operation of his work or if an abnormal situation is emerging.

In all cases, the appearance of broken ACCROPODE ™, ACCROPODE ™ II, CORELOC ™, ECOPODE ™ or X-bloc ® blocks indicates that movements of sufficient amplitude to cause breakage of the blocks have appeared.

The second thing to do is to look at the quality of the concrete used for the manufacture of ACCROPODE ™, ACCROPODE ™ II, CORELOC ™, ECOPODE ™ or X-bloc ® blocks:

Samples must be taken from broken blocks and nearby unbroken blocks and entrusted to an independent laboratory to analyze them.

In the majority of cases the quality of the concrete which is checked during construction will not be in question, but this hypothesis must always be studied.

If the swell that caused the damage is lower than the design swell and if the quality of the concrete is not in question, we must then investigate the cause of the movements that caused the breakage of the ACCROPODE ™, ACCROPODE ™ II blocks, CORELOC ™, ECOPODE ™ or X-bloc ®.

The third possible cause is the dismantling of the ACCROPODE ™, ACCROPODE ™ II, CORELOC ™, ECOPODE ™ or X-bloc ® blocks, which allowed movement and shock.

One cause of dismantling is a slippage of the foot of the structure. A switch to the multibeam sounder when the water is loaded or by diver or ROV when the water is clear will quickly highlight it.

ACCROPODE™ inspection using the DIDSON acoustic camera

The other cause of dismantling is the poor interlocking of the ACCROPODE ™, ACCROPODE ™ II, CORELOC ™, ECOPODE ™ or X-bloc ® blocks which, under the action of the swell and their own weight, descend to reach their final position. Only a dive inspection can reveal it, the acoustic tools manipulated from the surface do not allow it, except in extreme, rare and isolated cases.

SECOND CASE

Damage suddenly appeared on the structure

As before, you must know the limits of the design of the structure and confirm the good quality of the concrete. However, a sudden slip of the armour will find its origin in a departure from the foot of the structure.

STUDY OF DAMAGE CAUSES ON AN ACCROPODE ™, ACCROPODE ™ II, CORELOC ™, ECOPODE ™ or X-BLOC ® SHELL

Cause 1 The start of the foot of the armour protection

This destruction mechanism is simple: the materials that support the foot of the structure did not stand up to the swell and the current and were carried away. Heavy materials, riprap or blocks ACCROPODE ™, ACCROPODE ™ II, CORELOC ™, ECOPODE ™ or X-bloc ® are lowered into the slope thus formed.

ACCROPODE ™ II of the first row down on the slope

It will be highlighted quickly and easily by a survey using a multibeam sounder in all cases, by diver or ROV in clear water.

The stability of the materials under the foot of the structure must be understood by the design studies of the structure. The departure of these materials which is the cause of a disaster will highlight a deficiency in the design studies. This destruction is generally rapid, brutal and spectacular.

Cause 2 Poor interlocking of blocks

ACCROPODE ™, ACCROPODE ™ II, CORELOC ™, ECOPODE ™ or X-bloc ® blocks obey the same basic rules as all building materials: they are subjected to gravity and under the action of their weight they descend. They find stability as soon as the supports compensate for the effect of the weight.

With materials of simple shapes, cubic for example, placed on identical blocks, this balance is final as is the case for the construction of a wall. With blocks with complex shapes such as ACCROPODE ™, ACCROPODE ™ II, CORELOC ™, ECOPODE ™ or X-bloc ® placed on a riprap slope this final balance must be sought. It’s interlocking blocks.

The diver guides the installation of an ACCROPODE ™ II to reach the final interlocking

When a brick is lowered on a wall, the downward movement ceases when it is in contact with the bricks below, it is stable immediately. If you push on it it won't go down any more.

When descending an ACCROPODE ™, ACCROPODE ™ II, CORELOC ™, ECOPODE ™ or X-bloc ® block on a slope, the downward movement is slowed down by contact with the underlayer, then by the concrete-to-concrete contacts . The mass of the ACCROPODE ™, ACCROPODE ™ II, CORELOC ™, ECOPODE ™ or X-bloc ® blocks is not enough to reach the final equilibrium position. If we push on it the block will go down again. When several blocks in the same area have the ability to descend further after being laid, the combined actions of the swell and the terrestrial attraction applied to the mass of the blocks will break the balance and the blocks will descend to nest better. This movement is accompanied in all cases of block breakage, hole formation and sometimes extraction of ACCROPODE ™, ACCROPODE ™ II, CORELOC ™, ECOPODE ™ or X-bloc ® blocks which are no longer properly interlocked and swept away by the swell.

ACCROPODE ™ destroyed following movement underwater

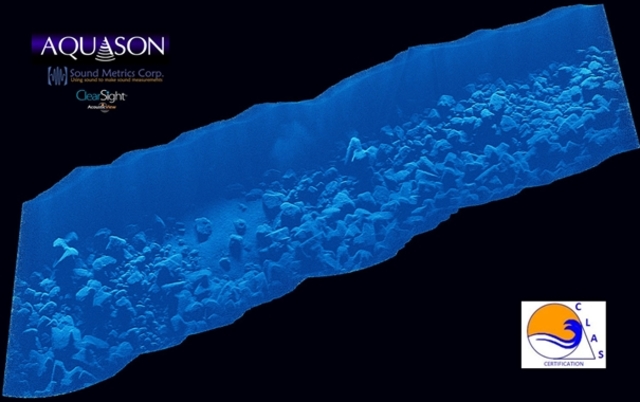

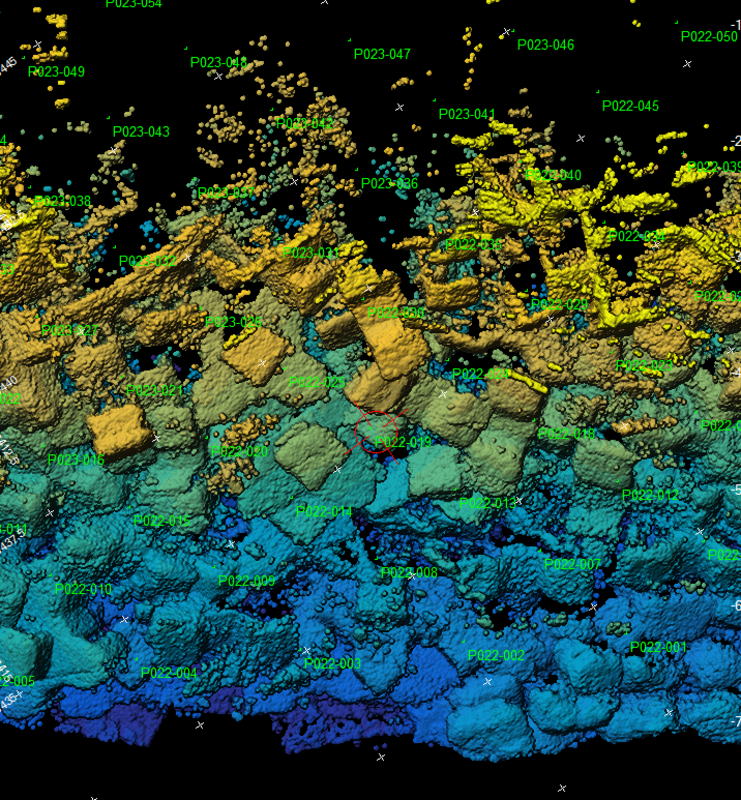

Inspection with acoustic tools will show ACCROPODE ™, ACCROPODE ™ II, CORELOC ™, ECOPODE ™ or X-bloc ® blocks which touch and appear to be interlocked. The diagnosis will be false due to the lack of clarity of the images produced and the lack of flexibility of the acoustic tool whose guided movements of the surface will not be free.

ACCROPODE ™ II on a multibeam view: it is impossible to appreciate the interlocking on this picture

We also evaluated the ECHOSCOPE in 2016 on theproject PUERTO MOIN at COSTA RICA:

Inspection with a diver expert will reveal contact faults between the blocks and positions which allow the ACCROPODE ™, ACCROPODE ™ II, CORELOC ™, ECOPODE ™ or X-bloc ® blocks to descend further. The diagnosis will be precise and the cause of the damage will be identified.

The diver can move in three dimensions and access any point of the armour to control the quality of the construction

The CLAS company is specialized in the installation of ACCROPODE ™, ACCROPODE ™ II, CORELOC ™, ECOPODE ™ or X-bloc ® blocks and the expertise of damage on the breakwaters.

We implemented and evaluated the ECHOSCOPE® and POSIBLOC ™ installation tools and acoustic tools like multibeam and the DIDSON and ARIS acoustic cameras.

Our inspectors are professional IMCA and HSE divers who know how to detect and show interlocking faults in ACCROPODE ™, ACCROPODE ™ II, CORELOC ™, ECOPODE ™ or X-bloc ® blocks.

There is also an additional cause that may facilitate the appearance of broken ACCROPODE ™, ACCROPODE ™ II, CORELOC ™, ECOPODE ™ or X-bloc ® blocks and worsen the consequences of improper interlocking of these blocks: the underlayer.

The riprap underlayer on which the ACCROPODE ™, ACCROPODE ™ II, CORELOC ™, ECOPODE ™ or X-bloc ® are placed must comply with the technical recommendations both with regard to the size of the riprap and the roughness of the surface pose.

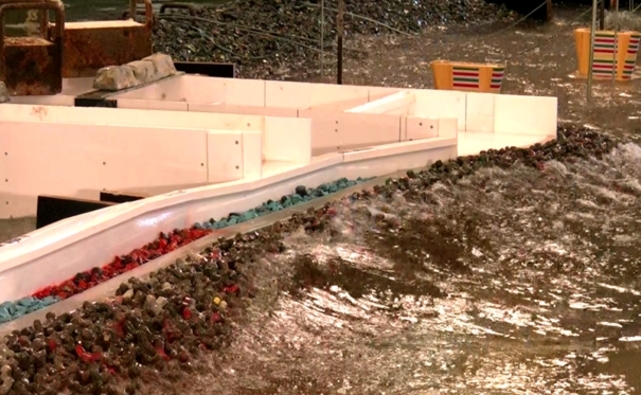

Control of the underlayer approved with multi-beam but not in conformity

After construction, the acoustic tools do not confirm compliance with the design under the ACCROPODE ™, ACCROPODE ™ II, CORELOC ™, ECOPODE ™ or X-bloc ® shell. The CLAS company has developed tools and a simple method but which can only be implemented by experienced and trained professional divers, which makes it possible to say if the underlay conforms to the design or if serious doubts exist. If the riprap is too small or if it is round as is the case with riprap from rivers, our inspectors will be able to see and show it without dismantling the ACCROPODE ™, ACCROPODE ™ II, CORELOC ™ blocks, ECOPODE ™ or X-bloc ®. In this case the underlayer will not be the primary cause of visible damage on ACCROPODE ™, ACCROPODE ™ II, CORELOC ™, ECOPODE ™ or X-bloc ® blocks but will be an aggravating factor because it will have facilitated the movements of descending of the blocks under the action of the swell.

PRAT DE BAIX EDIFICI F PB3, SOLDEU, AD100 CANILLO

+376 354 698 / +336 161 602 74

e...@clascertification.com

Clas certification - 2018 - Tous droits réservés - Mentions légales - Design : Pygmalis - Intégration : Ingeitec